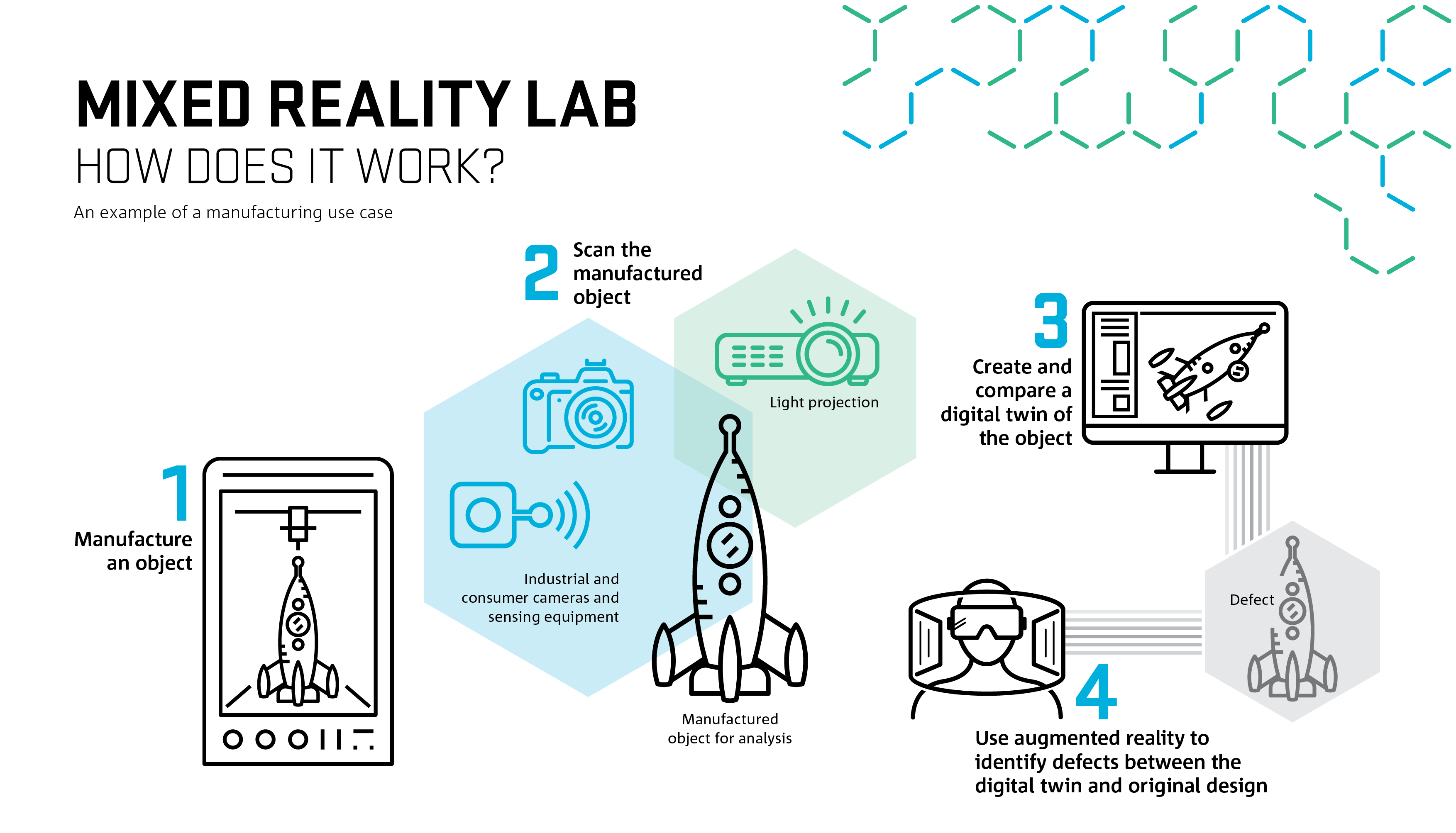

The Mixed Reality Lab at CSIRO’s Data61 will enable manufacturing and other industries to create 'Digital Twins', or virtual replicas of physical objects and systems.

The Mixed Reality component merges the real-time interactive physical and digital worlds, allowing the user to view the digital twin via a computer or augmented reality set.

"By comparing a digital twin of a manufactured object against the original design, we can quickly, accurately and cost-effectively identify defects and map entire manufacturing processes across a global supply chain," explained Matt Bolger, senior software engineer at CSIRO’s Data61. "Defective components can be identified in real-time and corrected, while downstream processes can be adjusted to minimise the impact of delays."

Located in Clayton, the lab houses a set-up of industrial and consumer optical cameras and sensing equipment to capture detailed information about a physical object and the space surrounding it.

The equipment is underpinned by sophisticated algorithms (Workspace) which merge the enormous amounts of data collected to create a digital twin in a matter of minutes.

The lab is a unique combination of Data61's research expertise across machine learning, computer vision, computational modelling, IoT, and CSIRO's patented Stereo Depth Fusion technology for depth estimation.

Industry applications

With the ability to be scaled to the size of the object being scanned, the Mixed Reality Lab can be tailored to create products for a variety of businesses, including health, agriculture and mining.

"Our technology can also be applied to humans to analyse their movement, using deep learning and biomechanical modelling," said Mr Bolger.

"This could help elite athletes improve their performance and reduce workplace injuries."

By comparing a digital twin of a manufactured object against the original design, we can quickly, accurately and cost-effectively identify defects and map entire manufacturing processes across a global supply chain.

Defective components can be identified in real-time and corrected, while downstream processes can be adjusted to minimise the impact of delays.

The Mixed Reality Lab at CSIRO’s Data61 will enable manufacturing and other industries to create 'Digital Twins', or virtual replicas of physical objects and systems.

Digital twins could improve product innovation and productivity by 25 per-cent by 2020, according to the International Data Corporation.

The Mixed Reality component merges the real-time interactive physical and digital worlds, allowing the user to view the digital twin via a computer or augmented reality set.

"By comparing a digital twin of a manufactured object against the original design, we can quickly, accurately and cost-effectively identify defects and map entire manufacturing processes across a global supply chain," explained Matt Bolger, senior software engineer at CSIRO’s Data61. "Defective components can be identified in real-time and corrected, while downstream processes can be adjusted to minimise the impact of delays."

Located in Clayton, the lab houses a set-up of industrial and consumer optical cameras and sensing equipment to capture detailed information about a physical object and the space surrounding it.

The equipment is underpinned by sophisticated algorithms (Workspace) which merge the enormous amounts of data collected to create a digital twin in a matter of minutes.

The lab is a unique combination of Data61's research expertise across machine learning, computer vision, computational modelling, IoT, and CSIRO's patented Stereo Depth Fusion technology for depth estimation.

Industry applications

With the ability to be scaled to the size of the object being scanned, the Mixed Reality Lab can be tailored to create products for a variety of businesses, including health, agriculture and mining.

"Our technology can also be applied to humans to analyse their movement, using deep learning and biomechanical modelling," said Mr Bolger.

"This could help elite athletes improve their performance and reduce workplace injuries."

Infographic showing how the Mixed Reality Lab works. An example of a manufacturing use case:

By comparing a digital twin of a manufactured object against the original design, we can quickly, accurately and cost-effectively identify defects and map entire manufacturing processes across a global supply chain.

Defective components can be identified in real-time and corrected, while downstream processes can be adjusted to minimise the impact of delays.