How we help the industry apply food and ingredient technologies

Our food and ingredient technology team helps companies to:

- develop new food and beverage products with desirable health and sensory attributes by

- improving the sensory properties and perception of food through control of flavour and taste release

- meeting national targets in reducing salt, sugar and fat in manufactured foods through design of food microstructure

- increasing protein, fibre, fruit and vegetable content in processed foods

- develop new ingredients for health and nutrition by

- enhancing the bioavailability of nutrients, bioactives and nutraceuticals

- designing microencapsulated ingredients to stabilise sensitive bioactives and nutraceuticals

- masking undesirable taste and odour from nutraceuticals and bioactive ingredients for increased consumer acceptance of fortified foods

- capitalise on inherent functionality and nutrients present in agri-food materials by

- adding value to food-waste streams, by-products from food processing and second grade produce

- applying traditional and emerging food processes to stabilise nutrients and high value components in food processing waste

- characterise and tailor food material properties by

- designing microstructures and functionality to improve stability and processability

- controlling the rate of digestion of target nutrients using a range of in-vitro models that simulate specific digestive functions

- enhancing the bioaccessibility and transport of nutrients in the body to improve nutrition delivery through ingredient design.

Food and ingredient technologies case study: development of microencapsulated omega-3 ingredients

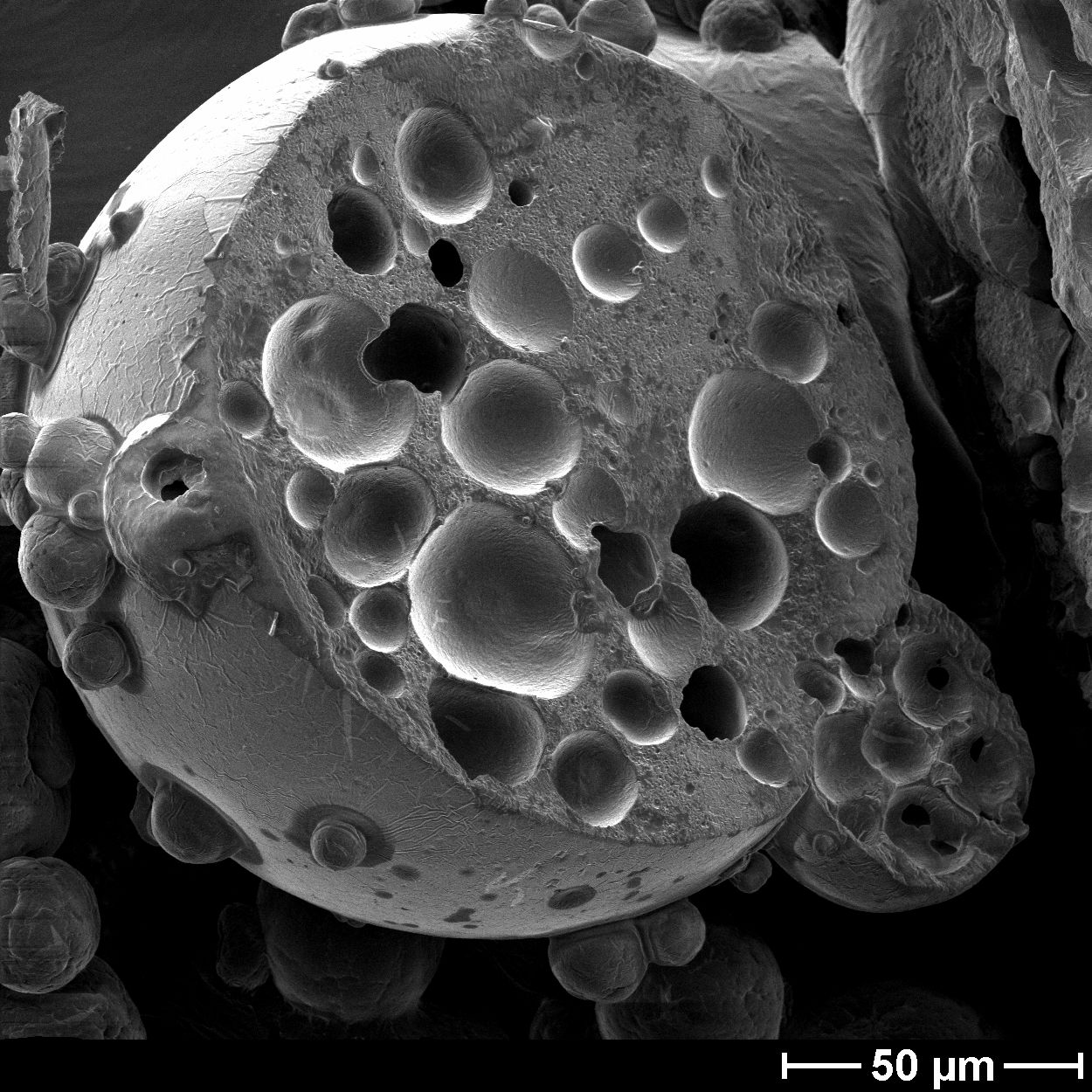

Fish oil is a good source of omega-3 fatty acids but is prone to oxidation and development of off-odours and flavours. CSIRO’s scientists overcame these problems by developing a technology that encloses microscopic droplets of fish oil in a food grade material. MicroMAX® masks the fishy flavour and extends the shelf life of omega-3 oils. The technology has unmatched encapsulation efficiency, oil loading capacity and stability.

Fish oil is a good source of omega-3 fatty acids but is prone to oxidation and development of off-odours and flavours. CSIRO’s scientists overcame these problems by developing a technology that encloses microscopic droplets of fish oil in a food grade material. MicroMAX® masks the fishy flavour and extends the shelf life of omega-3 oils. The technology has unmatched encapsulation efficiency, oil loading capacity and stability.

Fifteen years ago, Clover Corporation, then a small nutrition technology ingredient company based in Melbourne’s West, licensed the technology from CSIRO and since then have been manufacturing omega-3 powdered ingredients using CSIRO’s MicroMAX® technology for local and international food and infant formula companies.

Australian supermarket shelves are now stocked with a range of healthy omega-3 enriched food choices created using this unique encapsulation system.

Our key resources in food and ingredient technologies available to industry

Key CSIRO infrastructure and expertise available for industry include:

- food scientists, technologists, nutritionists, chemists, microbiologists and analysts with track records in solving food and ingredient innovation challenges

- food and process engineers with expertise in designing new processes and applying traditional and innovative unit processes

- internationally recognised experts in microencapsulation

- a comprehensive range of analytical equipment for physical characterisation and chemical analysis of raw materials, ingredients and final food products, including in-vitro analysis

- fully equipped product development test kitchens and lab-scale processing equipment

- $50m research and development pilot plant for processing a wide range of products including dairy, meat, grains, horticulture and packaged foods and beverages.

Welcome to CSIRO's food innovation centre

How we help the industry apply food and ingredient technologies

Our food and ingredient technology team helps companies to:

- develop new food and beverage products with desirable health and sensory attributes by

- improving the sensory properties and perception of food through control of flavour and taste release

- meeting national targets in reducing salt, sugar and fat in manufactured foods through design of food microstructure

- increasing protein, fibre, fruit and vegetable content in processed foods

- develop new ingredients for health and nutrition by

- enhancing the bioavailability of nutrients, bioactives and nutraceuticals

- designing microencapsulated ingredients to stabilise sensitive bioactives and nutraceuticals

- masking undesirable taste and odour from nutraceuticals and bioactive ingredients for increased consumer acceptance of fortified foods

- capitalise on inherent functionality and nutrients present in agri-food materials by

- adding value to food-waste streams, by-products from food processing and second grade produce

- applying traditional and emerging food processes to stabilise nutrients and high value components in food processing waste

- characterise and tailor food material properties by

- designing microstructures and functionality to improve stability and processability

- controlling the rate of digestion of target nutrients using a range of in-vitro models that simulate specific digestive functions

- enhancing the bioaccessibility and transport of nutrients in the body to improve nutrition delivery through ingredient design.

Food and ingredient technologies case study: development of microencapsulated omega-3 ingredients

Fish oil is a good source of omega-3 fatty acids but is prone to oxidation and development of off-odours and flavours. CSIRO’s scientists overcame these problems by developing a technology that encloses microscopic droplets of fish oil in a food grade material. MicroMAX® masks the fishy flavour and extends the shelf life of omega-3 oils. The technology has unmatched encapsulation efficiency, oil loading capacity and stability.

Fifteen years ago, Clover Corporation, then a small nutrition technology ingredient company based in Melbourne’s West, licensed the technology from CSIRO and since then have been manufacturing omega-3 powdered ingredients using CSIRO’s MicroMAX® technology for local and international food and infant formula companies.

Australian supermarket shelves are now stocked with a range of healthy omega-3 enriched food choices created using this unique encapsulation system.

Our key resources in food and ingredient technologies available to industry

Key CSIRO infrastructure and expertise available for industry include:

- food scientists, technologists, nutritionists, chemists, microbiologists and analysts with track records in solving food and ingredient innovation challenges

- food and process engineers with expertise in designing new processes and applying traditional and innovative unit processes

- internationally recognised experts in microencapsulation

- a comprehensive range of analytical equipment for physical characterisation and chemical analysis of raw materials, ingredients and final food products, including in-vitro analysis

- fully equipped product development test kitchens and lab-scale processing equipment

- $50m research and development pilot plant for processing a wide range of products including dairy, meat, grains, horticulture and packaged foods and beverages.