Challenge

Australian Bay Lobster Producers (ABLP) is a grower and supplier of premium-quality Bay Lobsters, also known as Moreton Bay bug, from their highly controlled production facility on the north coast of New South Wales. A key concern for the company is monitoring of their growth tanks where maintaining health of the colony of lobsters is key. Animal health data such as number of animals, feed volumes, and animal sizes is important for production management and decision making. Additionally, dead or diseased animals can impact on the water quality and the wider colony and need to be rapidly identified and removed. These tasks have been carried out by employees looking through the tanks to observe and count data, resulting in delayed decision making. A process that is time consuming and costly.

Solution

ABLP recognised that this task could potentially be automated using emerging digital techniques and engaged Professor Yongsheng Gao, an expert in machine vision and biometric technology at Griffith University in Brisbane Queensland. Professor Gao worked with ABLP to propose a digital vision solution coupled with digital processing, identification and classification techniques.

Together they secured a SIEF STEM+ Business grant to support Research Fellow Dr Xun 'Alex' Yu who has recently completed a PhD in Engineering with his thesis on '3D Face Recognition Based on Structural Representation'. Alex began the project by spending 3 days a week onsite at ABLP to gain a deep understanding of the challenge and getting to know the company’s staff. With the support of the ABLP and Griffith team Alex developed a prototype system with digital cameras that could monitor the lobster tanks 24/7 and capture visual information about the lobsters which he could take back to Griffith and use a basis to create recognition software.

Results

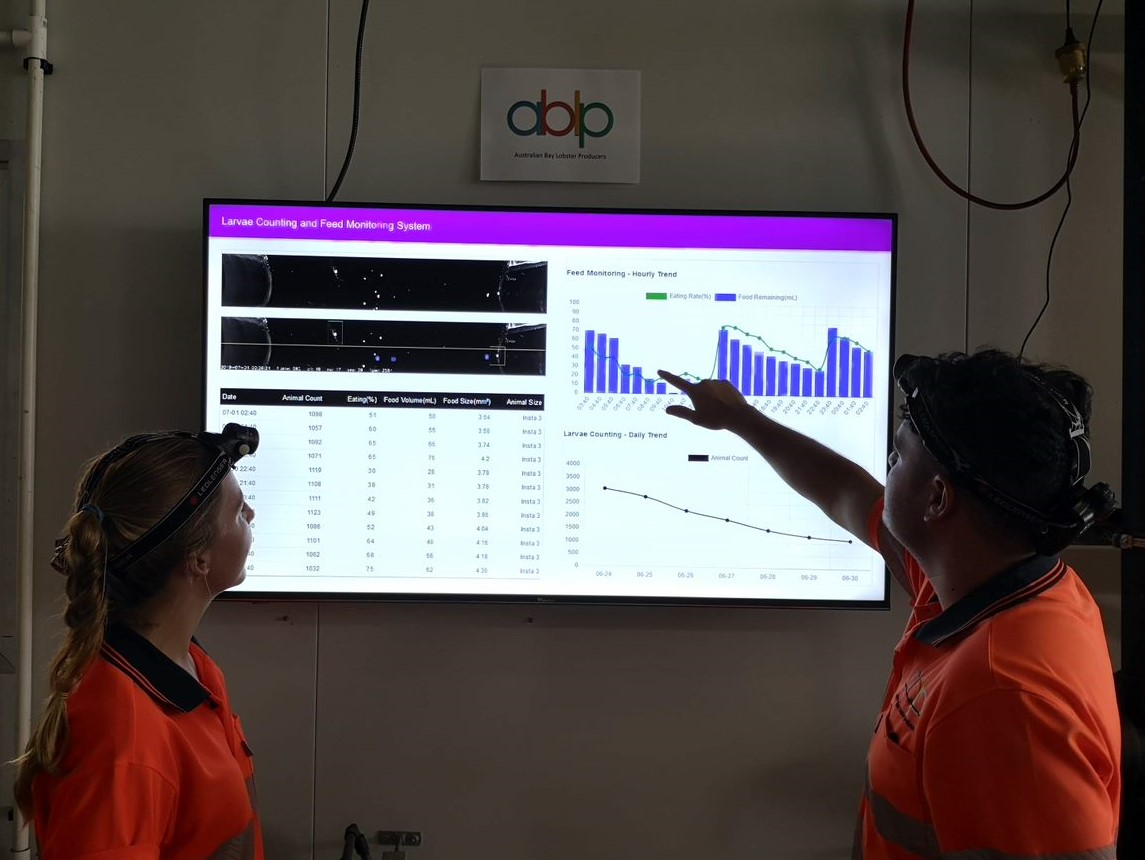

After a presentation by Dr Yu to ABLP management on the good results achieved by the prototype system the company has begun the process of integrating these world-first technologies into the production environment. This includes the installation of a large screen in the facility that will provide live updates on characteristics of the lobster colony. Alex continues to spend up to two days a week at the company as it seeks to adapt the technologies to a new production model. ABLP has seen that the project is on track to provide positive benefit in the short term but has importantly provided the foundation for significant operational benefit in the future.

“The SIEF STEM+ Business Project has supported the development of pioneering technology through collaboration. The innovations have practical applications and will lead to progressive outcomes for a primary industry.”

— John Bryant, Finance Director, Australian Bay Lobster Producers

This program is supported by the Science and Industry Endowment Fund (SIEF)

For further information and to apply, please get in touch with our dedicated STEM+ Business Manager.

Challenge

Australian Bay Lobster Producers (ABLP) is a grower and supplier of premium-quality Bay Lobsters, also known as Moreton Bay bug, from their highly controlled production facility on the north coast of New South Wales. A key concern for the company is monitoring of their growth tanks where maintaining health of the colony of lobsters is key. Animal health data such as number of animals, feed volumes, and animal sizes is important for production management and decision making. Additionally, dead or diseased animals can impact on the water quality and the wider colony and need to be rapidly identified and removed. These tasks have been carried out by employees looking through the tanks to observe and count data, resulting in delayed decision making. A process that is time consuming and costly.

Solution

ABLP recognised that this task could potentially be automated using emerging digital techniques and engaged Professor Yongsheng Gao, an expert in machine vision and biometric technology at Griffith University in Brisbane Queensland. Professor Gao worked with ABLP to propose a digital vision solution coupled with digital processing, identification and classification techniques.

Together they secured a SIEF STEM+ Business grant to support Research Fellow Dr Xun 'Alex' Yu who has recently completed a PhD in Engineering with his thesis on '3D Face Recognition Based on Structural Representation'. Alex began the project by spending 3 days a week onsite at ABLP to gain a deep understanding of the challenge and getting to know the company’s staff. With the support of the ABLP and Griffith team Alex developed a prototype system with digital cameras that could monitor the lobster tanks 24/7 and capture visual information about the lobsters which he could take back to Griffith and use a basis to create recognition software.

Results

After a presentation by Dr Yu to ABLP management on the good results achieved by the prototype system the company has begun the process of integrating these world-first technologies into the production environment. This includes the installation of a large screen in the facility that will provide live updates on characteristics of the lobster colony. Alex continues to spend up to two days a week at the company as it seeks to adapt the technologies to a new production model. ABLP has seen that the project is on track to provide positive benefit in the short term but has importantly provided the foundation for significant operational benefit in the future.

“The SIEF STEM+ Business Project has supported the development of pioneering technology through collaboration. The innovations have practical applications and will lead to progressive outcomes for a primary industry.”

— John Bryant, Finance Director, Australian Bay Lobster Producers

This program is supported by the Science and Industry Endowment Fund (SIEF)

For further information and to apply, please get in touch with our dedicated STEM+ Business Manager.

Mr Jason Barkla

SME Business Manager