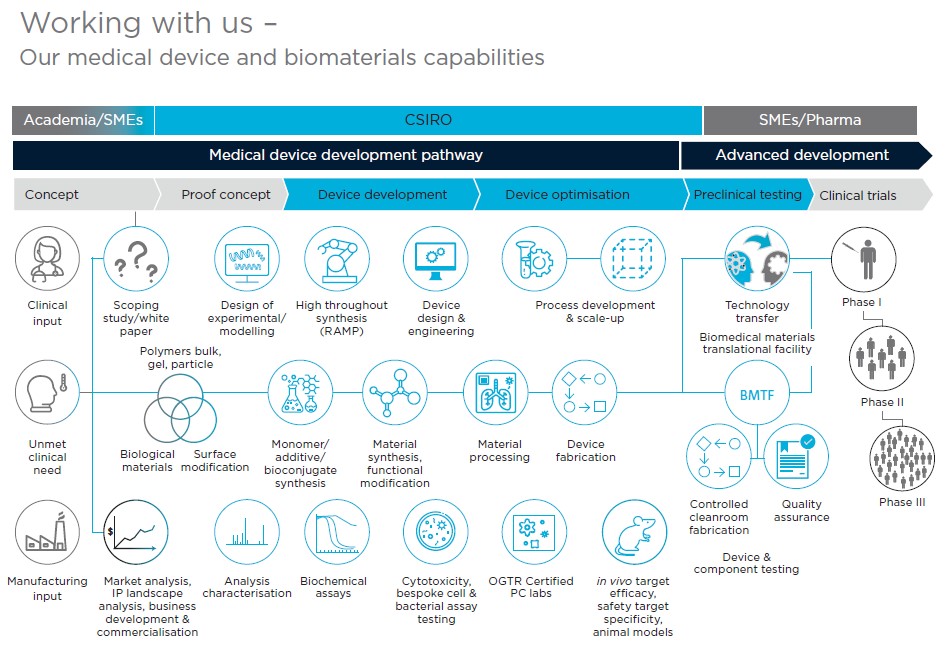

CSIRO’s team of researchers draw on skills across biology, chemistry, engineering and computer science. We collaborate with clinicians and industry to enable innovation of new materials and processes towards commercial reality. Our state-of-the-art facilities and infrastructure include high-through-put robotic synthesis platforms and ISO accredited labs for the fabrication and evaluation of prototypes.

This science ‘one-stop-shop’ focuses on translating great ideas into commercial successes, making CSIRO your ultimate R&D partner.

Case study: 3D printed silicone

Researchers from our biomedical polymers lab have developed a family of new silicone products. Parts printed with the silicone boast a suite of attributes including biocompatibility, super softness, great compressive elasticity, high transparency and tuneable mechanical properties.

The new resins are capable of printing complex designs in high resolution (see the example of a heart pictured above), including irregular shapes, thin walls and hollow structures. What’s more, they can be used with off-the-shelf printers, without any need for modification.

The silicones have applications in 3D printed medical devices and customised products such as dental devices, hearing aids and cochlear implants, prosthetics, and other patient specific medical devices. These unique ‘designer’ resins have the capability to help fast track prototyping some of these biomedical devices.

Download the factsheet

- Working with us – Biomedical devices and biomaterials

- Working with us – Biomedical devices and biomaterials (accessible text only)

CSIRO’s team of researchers draw on skills across biology, chemistry, engineering and computer science. We collaborate with clinicians and industry to enable innovation of new materials and processes towards commercial reality. Our state-of-the-art facilities and infrastructure include high-through-put robotic synthesis platforms and ISO accredited labs for the fabrication and evaluation of prototypes.

This science ‘one-stop-shop’ focuses on translating great ideas into commercial successes, making CSIRO your ultimate R&D partner.

Case study: 3D printed silicone

Researchers from our biomedical polymers lab have developed a family of new silicone products. Parts printed with the silicone boast a suite of attributes including biocompatibility, super softness, great compressive elasticity, high transparency and tuneable mechanical properties.

The new resins are capable of printing complex designs in high resolution (see the example of a heart pictured above), including irregular shapes, thin walls and hollow structures. What’s more, they can be used with off-the-shelf printers, without any need for modification.

The silicones have applications in 3D printed medical devices and customised products such as dental devices, hearing aids and cochlear implants, prosthetics, and other patient specific medical devices. These unique ‘designer’ resins have the capability to help fast track prototyping some of these biomedical devices.