Alumina comes from naturally occurring bauxite, and is used to make aluminium. Australia is the second largest producer of alumina in the world after China1. About 85 per cent of the alumina we produce is exported, providing $7.5 billion in exports2, while the rest goes to Australian smelters for aluminium production. However the alumina industry emits 14.9 million tonnes of carbon dioxide per year, which is three per cent of Australia’s total emissions2.

To reach Australia’s climate targets we need to decarbonise our alumina industry, and hydrogen is being considered as one of the technology solutions to achieve emissions reductions.

How alumina is made

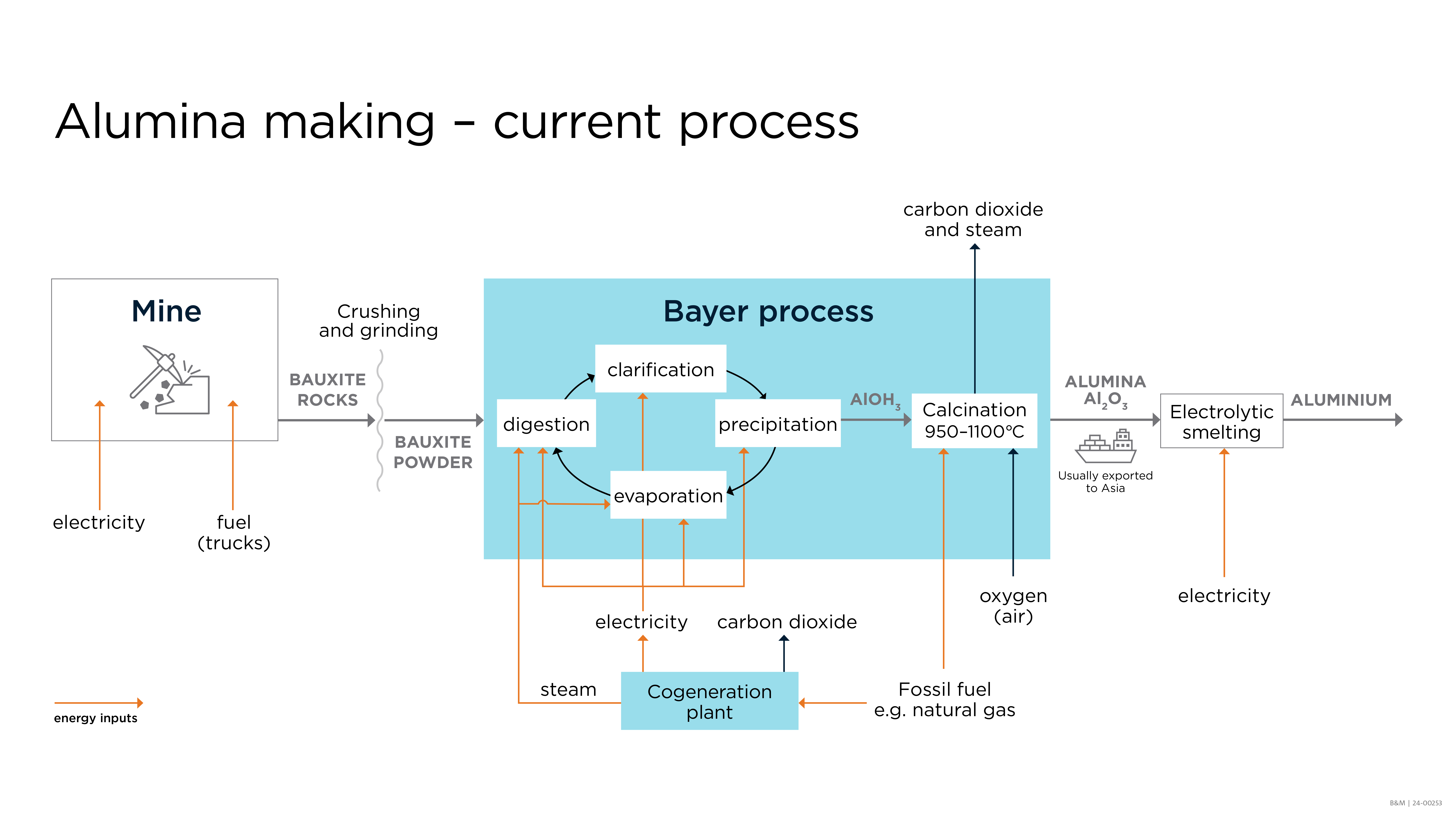

Bauxite rocks are dug out of the ground and transported from the mine to the alumina refinery, where they are mixed with spent process liquid and crushed into powder. The well-known ‘Bayer process’ produces an intermediate product called hydrate (AlOH3), which goes into the calciner to be converted to alumina (Al2O3). The simplified process is shown below.

Energy is required at every stage of the process. Australian alumina refineries have cogeneration plants, where a fossil fuel (usually natural gas) is burned in a boiler to produce steam. Some of the steam is put through a turbine to create electricity. Both the steam and the electricity are used in the alumina production process, and sometimes excess electricity is sent to the public grid.

Fossil fuel (usually natural gas) is also required in the calciner, where it is burned to produce the high grade heat and gas flow required to convert the hydrate to alumina.

How hydrogen can reduce greenhouse gas emissions

Hydrogen can be produced with no carbon emissions. For example, water can be split into hydrogen and oxygen in an electrolyser. If the electrolyser runs on renewable electricity (solar, wind, hydro), then the hydrogen is called ‘renewable hydrogen’ or ‘green hydrogen’.

Burning hydrogen produces only hot steam, (and sometimes some oxides of nitrogen depending on the burner design and conditions). So if hydrogen was used in the calciner instead of natural gas, the carbon dioxide emissions from the calciner would drop to zero, reducing overall carbon emissions from alumina production by up to 30 per cent. The steam coming out of the calciner (instead of carbon dioxide and steam) could also be reused as a heat source elsewhere in the Bayer process, improving the energy efficiency of the refinery.

Rio Tinto are preparing to trial the use of hydrogen in one of their calciners at their Yarwun refinery in Gladstone. The trial is expected to produce the equivalent of about 6,000 tonnes of alumina per year while reducing Yarwun’s carbon dioxide emissions by about 3,000 tonnes per year3.

Hydrogen could also potentially be used in the cogeneration plant in place of natural gas.

At the bauxite mine, diesel trucks could be replaced with hydrogen fuel cell electric trucks, which have a greater range and shorter refuelling time than electric trucks.

Challenges

The cost of renewable hydrogen is currently a significant barrier. Electrolysers are pricey, and current electricity costs combine to make renewable hydrogen a much more expensive fuel than fossil fuels.

The renewable hydrogen industry is in its infancy in Australia and around the world, although there are many plans to grow it quickly. To use renewable hydrogen in the alumina industry, a lot of new infrastructure would need to be built including renewable electricity (think solar panels, wind turbines and hydroelectric power), electrolysers and hydrogen storage.

Given that the use of hydrogen is a new method, there are some technical challenges to be overcome, such as development of the hydrogen burner system, and cleaning the steam out of the calciner before it can be reused.

Other ways of reducing greenhouse gas emissions from alumina production

A reliable supply of renewable electricity is key to reducing emissions from alumina refineries, and not just for hydrogen production.

The use of electric boilers could mean that the cogeneration plant runs on renewable electricity instead of fossil fuels. According to ARENA’s Roadmap for decarbonising Australian alumina refining, the combination of electric steam generation and hydrogen calcination could reduce a refinery’s emissions by up to approximately 98 per cent.

Many parts of the alumina production process release hot waste water vapour into the atmosphere. That water vapour could be recompressed into high pressure steam through a series of fans and compressors in a process called Mechanical Vapour Recompression. The high pressure steam could then be reused in the process, recovering waste heat that is otherwise lost. If the fans and compressors run on renewable electricity, then Mechanical Vapour Recompression is a way of making the refinery more energy efficient.

What CSIRO is doing

Our Hydrogen Industry Mission aims to support global decarbonisation through a commercially viable Australian hydrogen industry comprising both domestic and export value chains. We do that by leveraging our hydrogen research capabilities in partnership with government, industry and the Australian and international research communities.

CSIRO scientists are researching a number of different methods for the production and storage of renewable hydrogen. In our electrolyser research, we are aiming to make electrolysers more efficient (so that they use less electricity) and more cost-efficient.

We are also developing industrial hydrogen burners that mix hydrogen with air in a way that it burns safely with minimal co-production of oxides of nitrogen (nasties that contribute to acid rain ambient ozone, and even greenhouse gas emissions). Our burner designs could be used in numerous mineral processing plants.

We have expertise in Concentrated Solar Thermal technology, which has been identified as a potential enabling technology for decarbonisation of the alumina industry. Concentrated solar thermal works by using mirrors to concentrate the sun’s rays onto a central point, which contains a material such as molten salt. The energy is stored as heat, increasing the temperature of the molten salt. When the energy is required, such as when there is no renewable energy available, the hot molten salt can be used to make hot steam which can be used in the refinery or converted to electricity for the refinery.

Please contact us if you would like to work with us on hydrogen research and development.

Notes

Alumina comes from naturally occurring bauxite, and is used to make aluminium. Australia is the second largest producer of alumina in the world after China1. About 85 per cent of the alumina we produce is exported, providing $7.5 billion in exports2, while the rest goes to Australian smelters for aluminium production. However the alumina industry emits 14.9 million tonnes of carbon dioxide per year, which is three per cent of Australia’s total emissions2.

To reach Australia’s climate targets we need to decarbonise our alumina industry, and hydrogen is being considered as one of the technology solutions to achieve emissions reductions.

How alumina is made

Bauxite rocks are dug out of the ground and transported from the mine to the alumina refinery, where they are mixed with spent process liquid and crushed into powder. The well-known ‘Bayer process’ produces an intermediate product called hydrate (AlOH3), which goes into the calciner to be converted to alumina (Al2O3). The simplified process is shown below.

The process for making aluminium is shown in the diagram as follows:

Energy is required at every stage of the process. Australian alumina refineries have cogeneration plants, where a fossil fuel (usually natural gas) is burned in a boiler to produce steam. Some of the steam is put through a turbine to create electricity. Both the steam and the electricity are used in the alumina production process, and sometimes excess electricity is sent to the public grid.

Fossil fuel (usually natural gas) is also required in the calciner, where it is burned to produce the high grade heat and gas flow required to convert the hydrate to alumina.

How hydrogen can reduce greenhouse gas emissions

Hydrogen can be produced with no carbon emissions. For example, water can be split into hydrogen and oxygen in an electrolyser. If the electrolyser runs on renewable electricity (solar, wind, hydro), then the hydrogen is called ‘renewable hydrogen’ or ‘green hydrogen’.

Burning hydrogen produces only hot steam, (and sometimes some oxides of nitrogen depending on the burner design and conditions). So if hydrogen was used in the calciner instead of natural gas, the carbon dioxide emissions from the calciner would drop to zero, reducing overall carbon emissions from alumina production by up to 30 per cent. The steam coming out of the calciner (instead of carbon dioxide and steam) could also be reused as a heat source elsewhere in the Bayer process, improving the energy efficiency of the refinery.

Rio Tinto are preparing to trial the use of hydrogen in one of their calciners at their Yarwun refinery in Gladstone. The trial is expected to produce the equivalent of about 6,000 tonnes of alumina per year while reducing Yarwun’s carbon dioxide emissions by about 3,000 tonnes per year3.

Hydrogen could also potentially be used in the cogeneration plant in place of natural gas.

At the bauxite mine, diesel trucks could be replaced with hydrogen fuel cell electric trucks, which have a greater range and shorter refuelling time than electric trucks.

Challenges

The cost of renewable hydrogen is currently a significant barrier. Electrolysers are pricey, and current electricity costs combine to make renewable hydrogen a much more expensive fuel than fossil fuels.

The renewable hydrogen industry is in its infancy in Australia and around the world, although there are many plans to grow it quickly. To use renewable hydrogen in the alumina industry, a lot of new infrastructure would need to be built including renewable electricity (think solar panels, wind turbines and hydroelectric power), electrolysers and hydrogen storage.

Given that the use of hydrogen is a new method, there are some technical challenges to be overcome, such as development of the hydrogen burner system, and cleaning the steam out of the calciner before it can be reused.

Other ways of reducing greenhouse gas emissions from alumina production

A reliable supply of renewable electricity is key to reducing emissions from alumina refineries, and not just for hydrogen production.

The use of electric boilers could mean that the cogeneration plant runs on renewable electricity instead of fossil fuels. According to ARENA’s Roadmap for decarbonising Australian alumina refining, the combination of electric steam generation and hydrogen calcination could reduce a refinery’s emissions by up to approximately 98 per cent.

Many parts of the alumina production process release hot waste water vapour into the atmosphere. That water vapour could be recompressed into high pressure steam through a series of fans and compressors in a process called Mechanical Vapour Recompression. The high pressure steam could then be reused in the process, recovering waste heat that is otherwise lost. If the fans and compressors run on renewable electricity, then Mechanical Vapour Recompression is a way of making the refinery more energy efficient.

What CSIRO is doing

Our Hydrogen Industry Mission aims to support global decarbonisation through a commercially viable Australian hydrogen industry comprising both domestic and export value chains. We do that by leveraging our hydrogen research capabilities in partnership with government, industry and the Australian and international research communities.

CSIRO scientists are researching a number of different methods for the production and storage of renewable hydrogen. In our electrolyser research, we are aiming to make electrolysers more efficient (so that they use less electricity) and more cost-efficient.

We are also developing industrial hydrogen burners that mix hydrogen with air in a way that it burns safely with minimal co-production of oxides of nitrogen (nasties that contribute to acid rain ambient ozone, and even greenhouse gas emissions). Our burner designs could be used in numerous mineral processing plants.

We have expertise in Concentrated Solar Thermal technology, which has been identified as a potential enabling technology for decarbonisation of the alumina industry. Concentrated solar thermal works by using mirrors to concentrate the sun’s rays onto a central point, which contains a material such as molten salt. The energy is stored as heat, increasing the temperature of the molten salt. When the energy is required, such as when there is no renewable energy available, the hot molten salt can be used to make hot steam which can be used in the refinery or converted to electricity for the refinery.

Please contact us if you would like to work with us on hydrogen research and development.