Improving roadway development

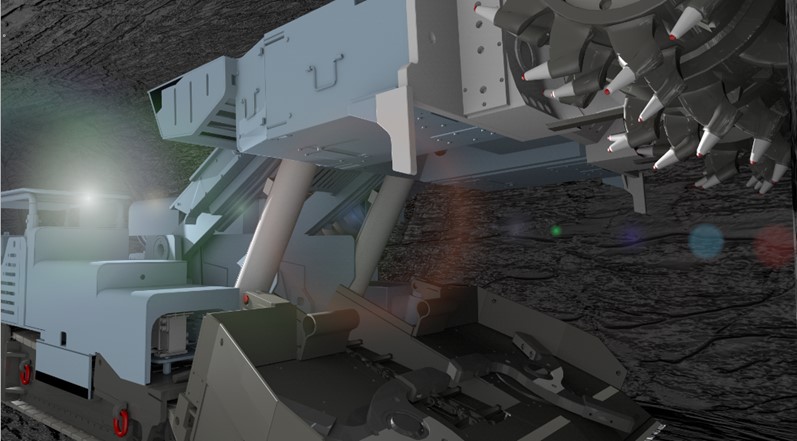

Advances in technology and equipment for longwall coal mining have led to rapid increases in production rates. But this has put pressure on roadway development, which has been identified as the limiting factor in the coal production supply chain. The roadway development process is based on the continuous miner (CM), equipment that cuts into coal seams to create the underground roadway systems necessary for the installation and operation of longwall equipment.

In response to an industry initiative to conduct research on new roadway development processes and technologies, we have developed a remotely-supervised CM. The key objective of the project has been to deliver a 'self-steering' capability. This capability will enable a CM to maintain 3D position, azimuth, horizon and grade control, all within a variable seam horizon and under remote operator supervision. The system will also provide real-time machine position to support autonomous bolting systems and haulage equipment.

Innovation in underground navigation

A step-change improvement in the accuracy, speed, robustness and safety of roadway development operations in underground mining is now possible with an innovative navigation solution. The Coal Mining Research Group has developed an inertial navigation system, which is designed for integration into existing underground mining equipment. The system provides real-time path and orientation information that gives operators an unprecedented level of insight to maintain mining activity, in accordance with the mine plan. The accuracy of the navigation system, along with the ability for its remote application, allows improved productivity and safety in underground mining operations.

Demonstrating the technology

This technology enables improved roadway development operations in underground coal mines across Australia and overseas. The navigation system has successfully demonstrated that it can accurately monitor the path of a roadway development mining machine under mining production conditions. Its key specifications include:

- robust and reliable measures of the path, position and orientation of underground mining machinery

- provides critical information for maintaining longwall roadway development, according to the mine plan

- real-time guidance information, available to the operation both locally and remotely

- the technology can be applied to Continuous Miners from all the major equipment manufacturers

- highly robust solution, based on a custom-designed and industry-proven hardware platform.

Improving roadway development

Advances in technology and equipment for longwall coal mining have led to rapid increases in production rates. But this has put pressure on roadway development, which has been identified as the limiting factor in the coal production supply chain. The roadway development process is based on the continuous miner (CM), equipment that cuts into coal seams to create the underground roadway systems necessary for the installation and operation of longwall equipment.

In response to an industry initiative to conduct research on new roadway development processes and technologies, we have developed a remotely-supervised CM. The key objective of the project has been to deliver a 'self-steering' capability. This capability will enable a CM to maintain 3D position, azimuth, horizon and grade control, all within a variable seam horizon and under remote operator supervision. The system will also provide real-time machine position to support autonomous bolting systems and haulage equipment.

Innovation in underground navigation

A step-change improvement in the accuracy, speed, robustness and safety of roadway development operations in underground mining is now possible with an innovative navigation solution. The Coal Mining Research Group has developed an inertial navigation system, which is designed for integration into existing underground mining equipment. The system provides real-time path and orientation information that gives operators an unprecedented level of insight to maintain mining activity, in accordance with the mine plan. The accuracy of the navigation system, along with the ability for its remote application, allows improved productivity and safety in underground mining operations.

Demonstrating the technology

This technology enables improved roadway development operations in underground coal mines across Australia and overseas. The navigation system has successfully demonstrated that it can accurately monitor the path of a roadway development mining machine under mining production conditions. Its key specifications include:

- robust and reliable measures of the path, position and orientation of underground mining machinery

- provides critical information for maintaining longwall roadway development, according to the mine plan

- real-time guidance information, available to the operation both locally and remotely

- the technology can be applied to Continuous Miners from all the major equipment manufacturers

- highly robust solution, based on a custom-designed and industry-proven hardware platform.