Arguably, the real innovation in CSIRO's new underground mapping technology, ExScan, is not the smart laser-based scanner, but the container in which it sits.

The enclosure has been certified to International Electrotechnical Commission 'Ex d' standards for use in volatile, methane-rich underground environments such as coal mines. That means it has been designed to prevent the electronic equipment it houses sparking an explosion.

Real time 3D scanner in explosion proof casing

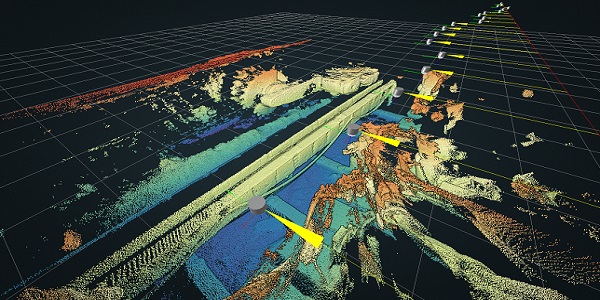

The laser scanner and associated software is capable of generating real time 3D maps of tunnels, walls and cavities underground where global positioning system (GPS) does not penetrate. These maps can be used for locating, steering and navigating equipment and vehicles.

"Nothing can go underground in a coal mine unless it's certified to be in that environment," CSIRO electronic engineer and ExScan project lead, Peter Reid, says.

"You can't even take an aluminium can; it's a potential spark hazard if it gets crushed by a vehicle. So getting electronics down there is a tricky process."

The problem is that explosive gases such as methane penetrate equipment, and any failure of electronics that causes a spark could lead to a fiery disaster.

Spark proof to prevent explosion

The solution outlined in the Ex d regulations, is not to contain explosions, but to prevent them from happening in the first place. That's achieved by designing the container to ensure any spark would have to travel such a long way to encounter sufficient gas to trigger an explosion, and by that time, it will have cooled below the ignition point.

Many members of CSIRO's ExScan development team spent years working with industry on the Australian Coal Association Research Program-funded project that developed the successful LASC longwall automation system (see Longwall mining goes international)

Automated technology to increase worker safety

A major driver behind automating coal mining is to remove people from the dusty, hazardous environment near the coal face, but even the LASC automated equipment occasionally needed hands on human measurement to guide it through trickier parts of the coal seams. The idea behind ExScan was to provide images that could be used to make those measurements automatically.

"This technology provides us with information that cameras on their own can't," Mr Reid says.

"It allows us to measure in 3D anything we see, as if we were there."

The team was ideally suited to the job. Not only did the researchers have a lot of knowledge about what the industry needed but, through CSIRO, they also had access to expertise in smart design and working with materials such as plastics.

R2-D2 in a polycarbonate dome

What emerged looks a little like a 25-centimetre-high version of Star Wars character R2-D2 – with a steel base into which a polycarbonate dome screws. The laser sits under the transparent dome and scans through it. To get outside into a volume of gas, any spark generated would have to work its way through a narrow sawtooth path formed by the screw thread, and in doing so, would lose most of its energy.

Should the scanner malfunction or the container become scratched or damaged, it can be swapped over in a matter of minutes, because the dome just screws off.

Affordable technology for multiple installations along longwall

The team invested a lot of time in computer modelling to come up with a dome that was just right for injection moulding. That makes the ExScan devices relatively inexpensive to manufacture. In fact, they are affordable enough for a line of 40 or 50 to sit behind the mining equipment along a longwall face of between 400 and 500 metres in length, providing real time updates of the condition of the wall. At 10 metres apart, the devices are close enough to allow redundancy – their scans overlap, which means that if one fails, its absence can be covered by others on either side to ensure overall reliability.

Oakey Creek Mine demonstration with Glencore

According to Glencore technology superintendent at Oaky North Mine in central Queensland, Lauris Hemmings, the images they generate can be used to determine and sort out coal flow blockages on the conveyor system under the shearing equipment and to help align and steer the shearers themselves.

"It's a fantastic tool," Mr Hemmings says.

"An ever-evolving piece of equipment that takes risk management to even higher levels."

The mine is already hoping ExScan can be used to navigate the higher risk areas of the mine, taking employees away from the coal face.

But the applications are broader. The scanners can be mounted in any orientation, even upside down, and on moving machinery and vehicles. This means they can be used to map whole mines, and potentially for vehicle navigation.

The containers themselves can be employed for other electronic purposes, such as housing camera systems, and are already being marketed separately by Eaton Industries.

ExScan welcomed by industry

In addition to Glencore, the LASC ExScan system is being trialled by five other Australian mining companies, as well as by companies overseas. The Chinese coal industry has become so interested that it has invested the resources for a couple of engineers to develop skills to deal with the large amount of data generated by the scanners. The feedback from all this activity is allowing the CSIRO team to develop new features for the scanner.

CSIRO is now determining next steps to commercialise the ExScan system.